OUR KNOW-HOW

Passion for terroir

we

are

proud

and

protective

of

our

vines

and

our

terroir.

our

soil

is

our

legacy

.

OUR TEAM

Brice Bezin

Cellar Master and Head of Grape Supply Telmont

Emilie Sassa

Alcohol customs & scheduling Manager

Aurélie Nanquette

Communication & Hospitality Officer

Henrick Bouche

Production and Expedition Officer

Florence Berat

Office Manager

Ludovic du Plessis

President of Maison Telmont

Sylvain Pithois

Maintenance & Disgorgement Manager

Laurine Gagelin

Finance Manager

Justin Meade

Global Marketing & Business Development Director

Franck Barillet

Winery Officer

Alexis Lyon

Global Brand Manager

Célia Marchand

Packaging & Quality Officer

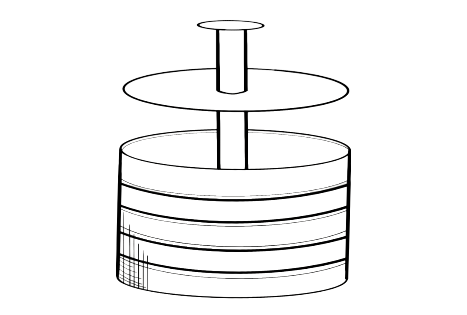

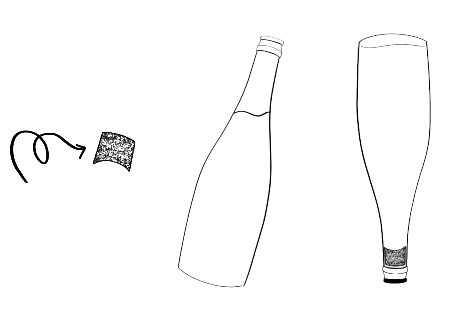

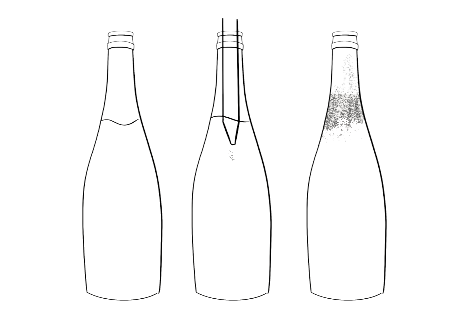

the

making

of

champagne

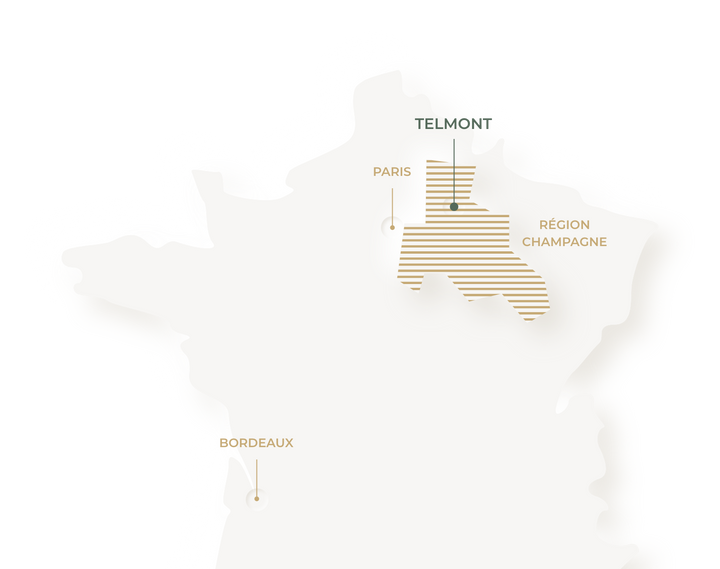

Champagne

region

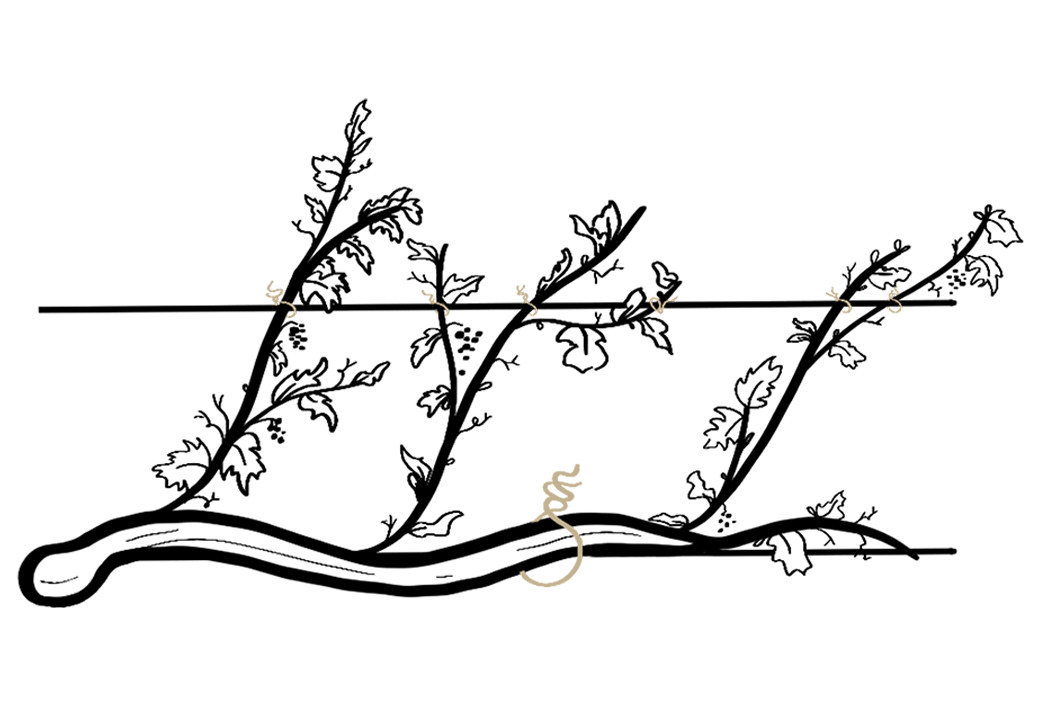

Excellence in its terroir, unique in its alliance of soil, climate and human craft. The Champagne appellation encompasses roughly 34,300 hectares of vineyards in the North East of France

Our

story

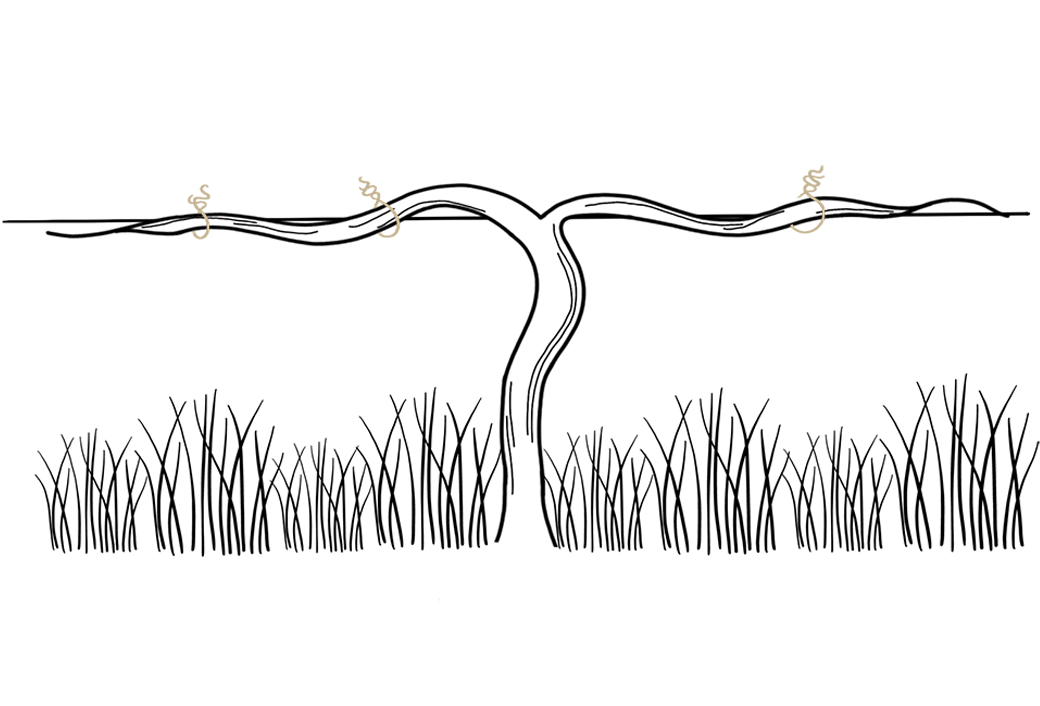

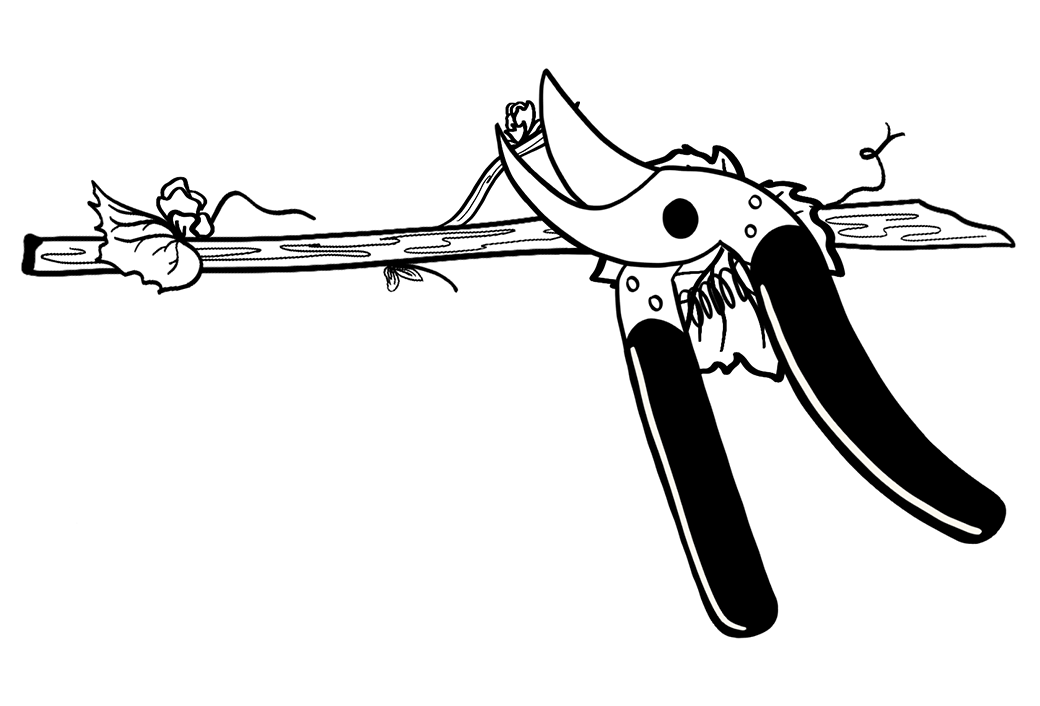

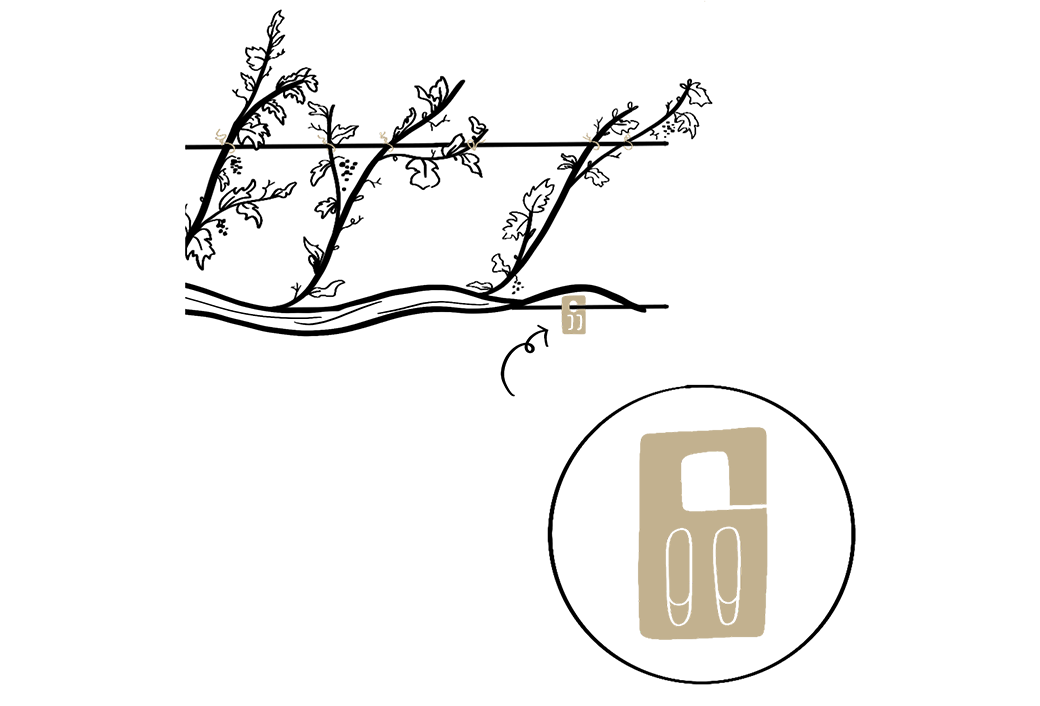

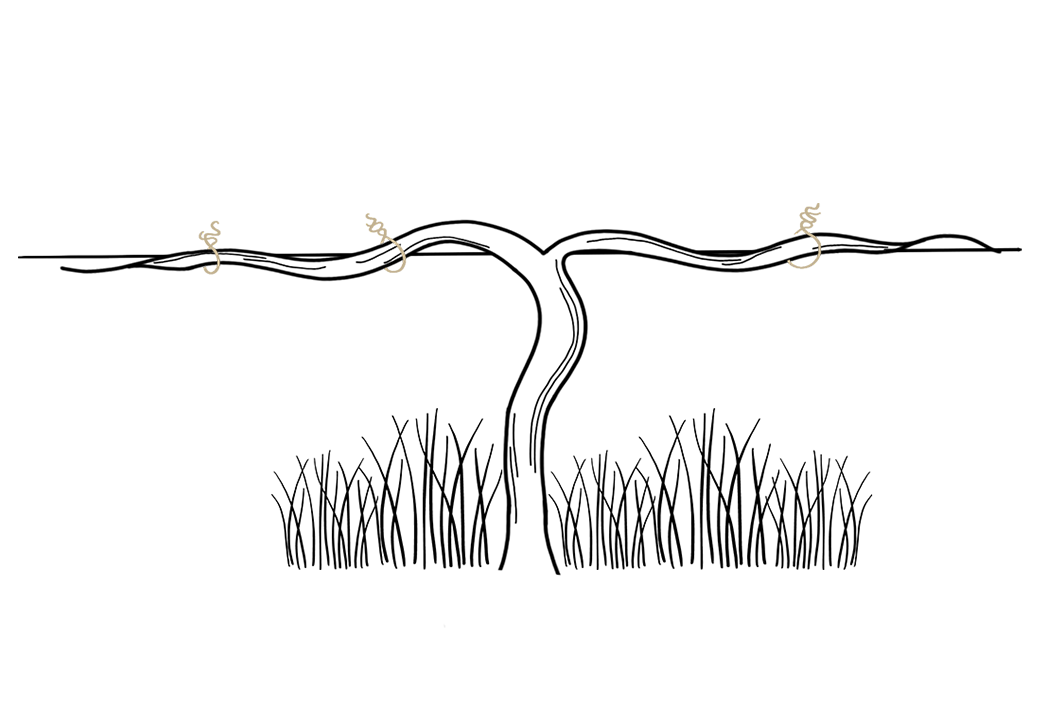

our house is as much at the heart of the vineyard as the vineyard is at the heart of our house.

Guided by our values, and by the eternal pursuit of excellence, ours is an approach that brings together tradition and sustainability.

Skip to content

Skip to content